What could be better than the aroma of fresh kebabs while relaxing in nature? A pleasant evening with friends at the dacha will always bring a lot of positive emotions. This is the best way to take a break from work, hustle and bustle and daily routine! Buying a barbecue is not the cheapest purchase. And why, if you can do it yourself?

1. Brazier made of sheet steel

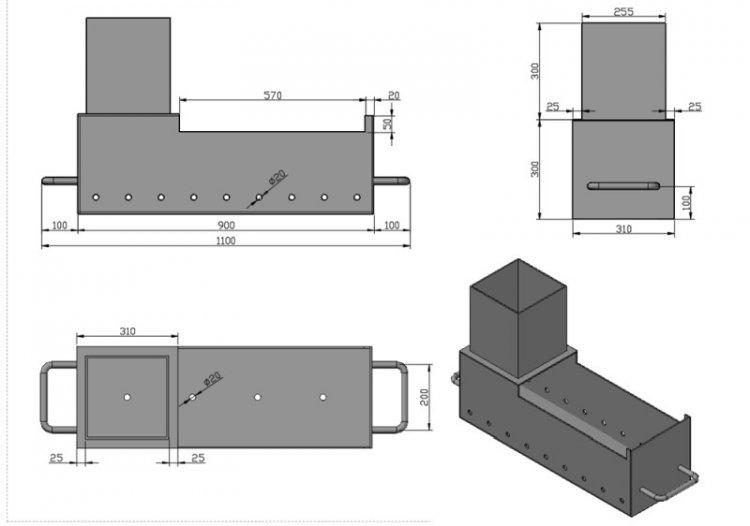

The simplest and most common manufacturing option is a barbecue made of sheet steel. It is easy to work with it, it is easy to assemble and requires a minimum of material, time and labor costs. Such barbecues are lightweight and mobile, but at the same time less durable due to their thin walls.

The welded brazier is good because it does not need additional mechanical fasteners. This is a good stationary option for a summer residence or a tourist base. Make legs from strong corners, build a foldable stand from profiles or a decorative wrought-iron base.

Cut vertical slots for skewers on the long walls. It is best to make several types of slots with different depths to regulate the amount of heat and cooking time. Holes were drilled at the bottom for drainage and ventilation, and on the sides, screw the carrying handles. From above, the structure can be painted with special heat-resistant enamel.

2. Steel brazier without welding

The method of making a steel barbecue without welding is actually almost the same as the classical scheme. You use corners, bolts, grooves and nuts only to connect all parts. This is a good option if you need a collapsible mobile structure that you can take with you.

Draw, mark and cut out all the details with a grinder or a hacksaw for metal. Fold the bottom of the sidewalls with a vise for easy and neat assembly. Likewise, process the junction of the long and short walls - in fact, you will have a box.

3. Stationary brick brazier

The first step is to find a suitable place, protected from wind and dust. The brick grill is stationary, so you will have to align and prepare the site, acquire a shed and communications. This is a good option for a covered gazebo or terrace with a table, chairs or sun loungers.

For the construction of the barbecue, take only refractory bricks, because silicate bricks cannot cope with such conditions. Choose a suitable drawing or compose several at once - it's easy to do even without experience. The brick grill is a kind of constructor, so you can experiment with shape and configuration.

For the foundation, dig a flat hole without height differences and with a margin of about 5 cm on all sides. Cover the bottom with slag, install the formwork, lay the reinforcing mesh and fill the structure with concrete. The foundation needs to stand for at least three days in order for it to completely dry out and harden.

To level the base, fill in a thin layer of screed and apply a layer of waterproofing. Lay out the firebox from solid refractory bricks, and the walls from ordinary hollow ones. Large massive structures are reinforced with metal rods for durability. As a canopy roof, you can use metal or polycarbonate.

4. Brazier made of stone

A stone brazier differs from a brick one for the most part only in appearance. It is massive, textured, spectacular, with a natural texture and bizarre shapes. Such a grill is easy to fit into the landscape design, and it fully complies with current eco-trends.

Making a stone brazier with your own hands is more difficult than a brick one, due to the preparation of materials. But in return you get amazing decorative properties and a real work of art. Structures with deliberately rough and chaotic masonry look very interesting.

You can safely take both natural and artificial stone: the first is stronger, and the second is easier to work with.Basically, these are granite, sandstone, shale, dolomite, quartzite or shungite. The most difficult work is to work with rough, uncouth cobblestones, easier - with flagstone, thallus or torn rubble. For laying, a cement-sand mixture or special compositions with modifiers are used.

The walls of a stone barbecue do not have to be perfectly flat, but definitely strong and stable. Thoroughly coat all joints with a solution, fit them tightly to each other and strengthen the weak points with a metal bar. It is important that all grill brackets and other items in the broiler are at the same level.

5. Brazier from a metal barrel

To make a small brazier with your own hands, you will need a 60 or 100 liter metal barrel. The paint on the surface will bubble with the temperature, so remove it with a sanding disc or stiff brush. Cut the barrel strictly according to the markings under the ruler, and then clean and grind the cuts. The average size of the lid is about a quarter of a circle with an indentation from the edges of 3-5 cm, although you can simply cut it in half.

To make the lid hinged, screw on conventional door hinges or furniture hinges for swing fronts. To make it convenient to open it, weld on the door handle, and to fix the barbecue in the open position, install a hook at the back. If you weld a steel tape along the edges of the cut, the lid will definitely not fall into the barrel.

Connect two wide pipes with a diameter of about 7 cm at an angle of 90 degrees. To do this, cut off their edge diagonally and weld the joint tightly, leaving no gaps. Cut a round hole on the side of the barrel and weld the finished chimney to it, and leave a few small holes for drainage from the bottom.

A sturdy rectangular tube measuring approx. 3 x 5 cm, ideal for a foldable or stationary stand. Thin steel rods make a grate holder. From the remains of a pipe or rod, make side handles to carry the brazier. The grate itself is cut from a stainless mesh, or just buy it ready for grilling.

6. Brazier from a gas cylinder

At its core, a gas cylinder is the same barrel, and a brazier is made from it according to the same principle. You don't even need to buy it specially - an old cylindrical propane cylinder with a volume of 50 liters will do. And from a 27-liter cylinder you will get an excellent mobile grill that you can carry with you in the trunk.

Pay special attention to safety measures - do not rush to cut the cylinder, even if there is no more gas inside, because condensate, propane residues and pressure still remain there. First unscrew the valve, empty the bottle, fill it with water, turn it over on its side and leave it there for at least a couple of hours.

Another advantage of the cylinder over the barrel is the presence of an almost finished outlet for the chimney. Just cut off the valve, cut the edges and weld the pipe in place. If you plan to use a grill with an open lid, then a chimney is not necessary at all!